Powerful Work 6X6 VOLVO A40G RC Hydraulic Articulated Dump Truck, Hydraulic VOLVO Heavy Rock Truck Hobby Scale Model

27 in stock

✅ A READY TO RUN VOLVO A40F RC DUMP TRUCK. This dump truck is strong, fully metal and has massive power. It weighs about 23 kilograms. It has real engine sound and an amazing light system.

✅ This is an advanced RC dump truck made for RC construction hobbyists.

$3,217.30 $3,217.40

27 in stock

1/14 Scale Full Metal Hydraulic Articulated Haulers, VOLVO A40G RC Articulating Dump Truck, (VOLVO A60H Rock Truck, VOLVO A45GFS Heavy Duty Truck, VOLVO A45G Heavy Equipment, VOLVO A35G Earthmoving Equipment, VOLVO A30G Construction Equipment, VOLVO A25G Heavy Duty Truck)

FULLY UPGRADED JDM 118 RC ARTICULATED HYDRAULIC DUMP TRUCK

A READY TO RUN VOLVO A40F RC DUMP TRUCK. This dump truck is strong, fully metal and has massive power. It weighs about 23 kilograms. It has real engine sound and an amazing light system.

N.B. This is an advanced RC dump truck made for RC construction hobbyists.

Need to pre-order: this machine is not already manufactured and they do require manufacturing after purchase. Depending on the workload or supply of raw materials, manufacturing of this model can take about 1 – 2 weeks.

Before shipments of this model. Heavy Duty RC RC’s expert test and make sure the machine is working perfectly before we proceed to give it to the Delivery courier. The machine will be shipped with an express courier and the transit time is usually about 10-17 days depending on the delivery address provided by the customer.

Product Specification:

• The material of this excavator is made of steel, zinc alloy and plastic

• It comes with 9 channel 2.4Ghz radio control.

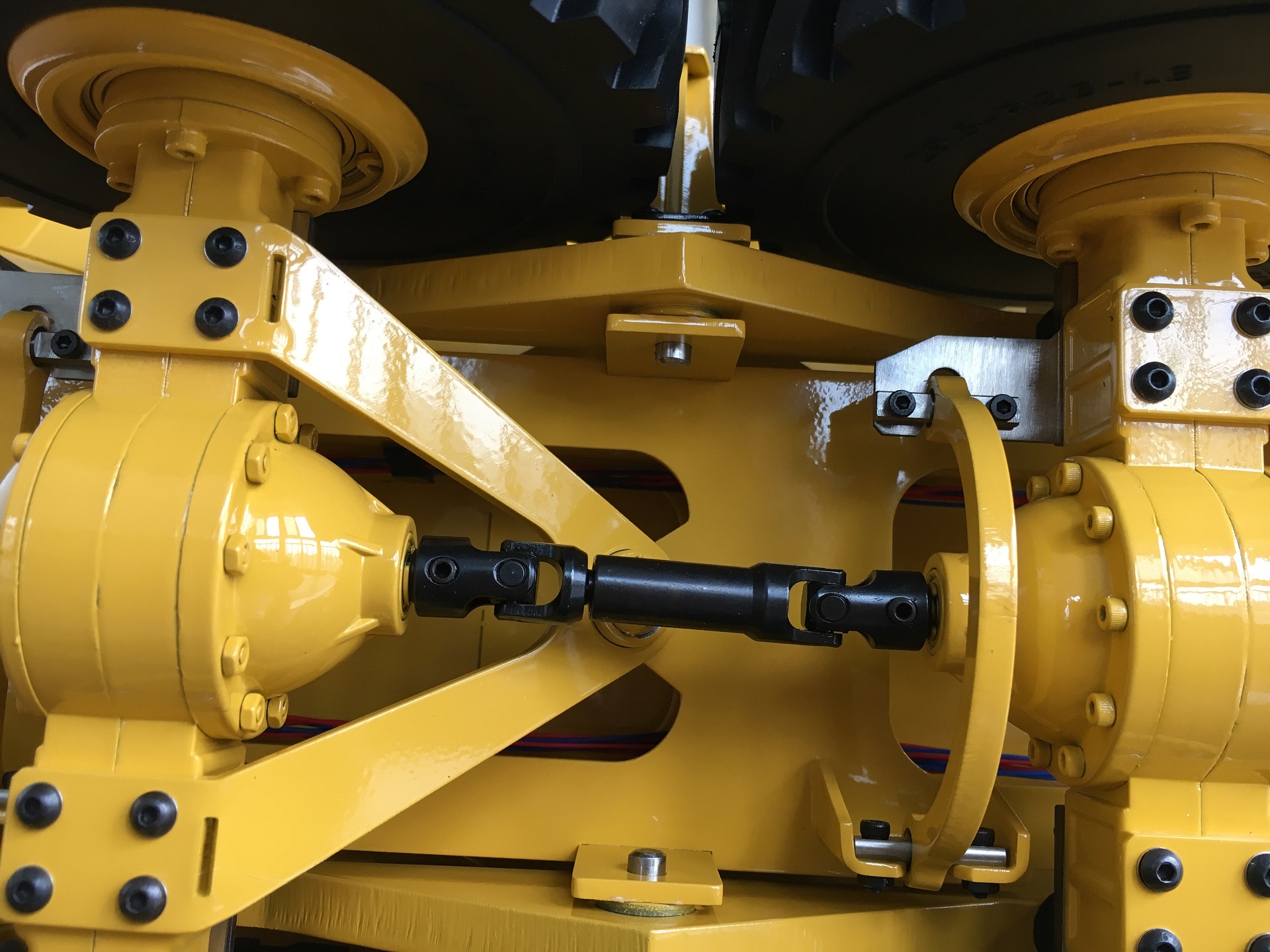

• It has an optimized steel hydraulic system

• This dump truck has an Efficient undercarriage

• It comes with a driving figure.

• The axles are zinc alloy.

• It has a reliable hydraulic valve and also an adjustable pump

• The engine has sound system.

• This dump truck has a light system

• Max undercarriage steering 40 degrees

• Steering system is hydraulic.

• Brushless driving system

• 6×6 driving mode with differential

• 800Kv brushless monster torque motor

• Battery: Lipo 3S,4200mAh,11.1V,XT60(battery not included)

• Steel machined hydraulic pump

• Scale: 1:14

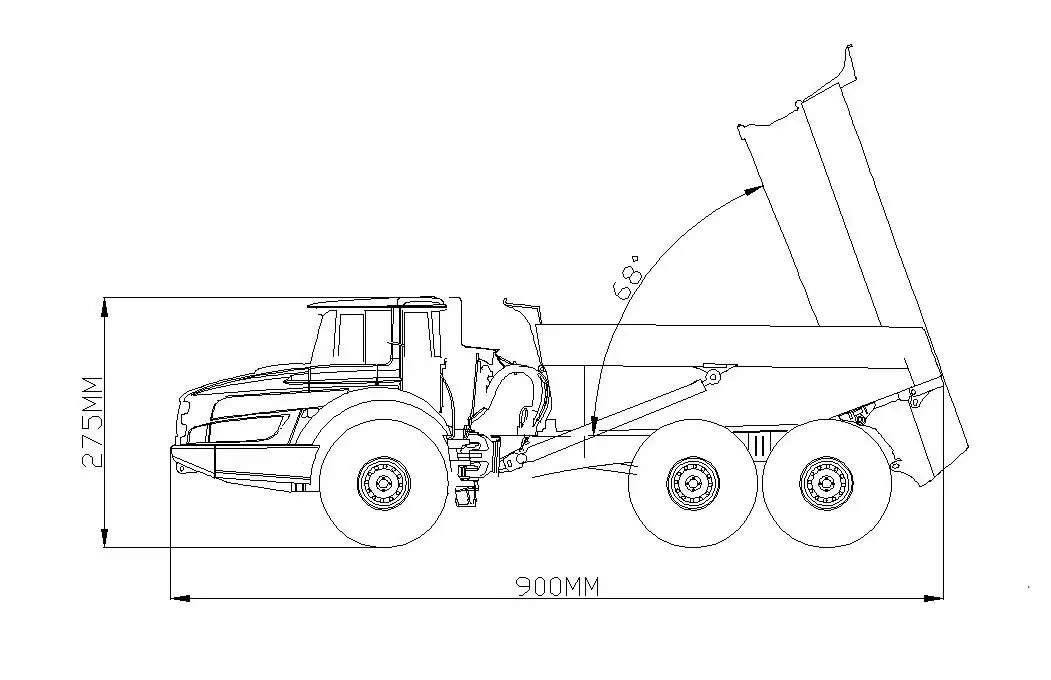

• Length: 900mm

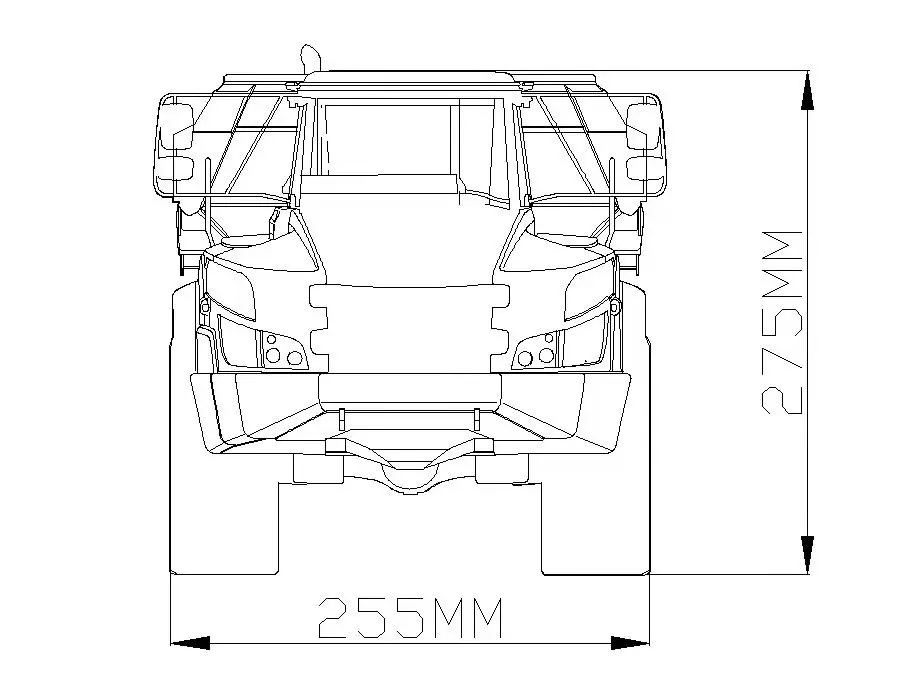

• Width: 255mm

• Dump truck Weight: 23kg

Packaging list:

RC Hydraulic Articulated Dumper

Radio Control

Battery

Charger

| UNBOXING XDRC ARTICULATED RC HYDRAULIC DUMP TRUCK DUMPER A40G VOLVO REPLICA, 6X6, RTR, SOUND, LIGHTS **Amazing rc hydraulic dump truck unboxing and first test!! RC Modell Hydraulik Dumper: XDRC Articulated rc hydraulic dumper dump truck Volvo A40G Replica Scale: 1/14 Model weight with drive battery 3S Lipo 2.200 mAh: 24,4 kg My purchase price on April 13, 2023: Euro 2.448,90 (about as 2.690 Dollar) as new buy from toucanhobby china at ebay germany Including remote control FlySky FS-i6S with Sound, Lights, RTR including: Lipo battery with XT60 connector for driving 3S 11,1V 2.200 mAh or higher mAh |

|

| RC Volvo A40G It is 900mm long and 255mm wide. Weight: 23 kg. Material: steel, zinc alloy, plastic. Rotate angle: 40 degrees. Steering mechanism: hydraulic steering. Walking power: Brushless power. axle: Zinc Alloy Die Casting . Driving mode: 6×6 The wheel side reduction axle has planetary gear and differential, no differential lock. Hydraulic pump: Brushless pump. Lifting mechanism: hydraulic lifting |

|

| Taking the New Volvo for a TEST DRIVE: A40G Rock Truck Winter 2019 -15c 1/14 scale | RC ADVENTURES This machine weighs approximately 50 lbs is what I would estimate. When I bought it, the ad read it was 75 lbs, but I dont believe it is. This is running on a 3s Lipo Battery, at about 12v. It is hydraulic fluid, and has a pump located under the hood. This was a limited edition model, and is currently not available for sale.. as they sold out quickly. I pounced on it when I had the opportunity, at the end of 2018. I had to wait 6 weeks for it to be built. The model is 6×6 (meaning 3 driven axles), they are all open differential. This makes for some creative driving in slippery conditions.. but as this is my first time out – you can see that with a little ingenuity and careful driving the truck can basically crawl anywhere. I think with a loaded dump bed, this machine would have mad traction. |

|

| RC Dump trucks 1:14 RC Volvo A40G and CAT 745D dump truck, 1:14 scale |

|

| Dream RC Machines 1/14 Dream RC Machines in action. |

Articulated hauler

An articulated hauler, articulated dump truck (ADT), or sometimes a dump hauler, is a very large heavy-duty type of dump truck used to transport loads over rough terrain, and occasionally on public roads. The vehicle usually has all-wheel drive and consists of two basic units: the front section, generally called the tractor, and the rear section that contains the dump body, called the hauler or trailer section. Steering is made by pivoting the front in relation to the back by hydraulic rams. This way, all wheels follow the same path, making it an excellent off-road vehicle.

Manufacturers include Volvo CE, Caterpillar, Terex, John Deere/Bell Equipment,[1] Moxy/Doosan, Astra and Komatsu Limited.[2] With half of the global sales, Volvo is the market leader in the segment, and is also the prime pioneer of the vehicle, enabling its introduction to the markets in 1966.

Although first envisioned as a soil and aggregate transporter (dumper), the chassis have since been used for many other applications including agriculture, mining, construction and highway maintenance. Ranging from concrete mixer, water tanker and container truck, over to upsize off-road semi-trailer hauler (on-road applications), hook loader or crane, as well as used to transport timber and as a woodchipper platform. Its chassis have also been used for military purposes given that it only is surpassed by tracked vehicles in off-road capabilities. An example is the Archer Artillery System.

| Volvo A40G Articulated Hauler – PUSHING POWER All-Volvo drivetrain delivers low fuel consumption and superior reliability. Articulation and oscillation joint has high ground clearance, maintenance-free rotating hitch design. Equipped with Volvo Care Cab, centrally positioned with ideally-placed pedals, controls and switches. Easy service access with front swing-down grill and 90 degree tilting hood. CareTrack telematics system. |

Volvo A40 RC hydraulic Articulated Dump Truck

| THS * VOLVO A40F DUMPER * FERRY TRIP * RC

THS * VOLVO A40F DUMPER * FERRY TRIP * RC |

|

| VOLVO A40G RC Dump Truck Die erste Testfahrt mit meinem neuen VOLVO .. Er wiegt unglaubliche 30kg !!! Mal schauen wie er sich weiter schlägt…. |

|

| 1/14 full metal hydraulic RC articulated truck DIM K745 Can you imagine what kind of big guy this is? With the light system and sound system! Ready to run! The size of it is 3*11*11.18 inches. Net weight about 20KG. |

|

| Volvo A40G RC dump truck traverses rough terrain off-road. Rc construction equipment RC 6×6 truck Roads? Where we can go we don’t need Roads! |

| Weight | 23 kg |

|---|---|

| Dimensions | 33 × 5 × 1000 cm |

1/14 Scale Volvo RC Hydraulic Articulated Dumper

Hydraulic Articulated/ Full Metal / Ready-to-Run / Battery Powered.

Very powerful RC model for heavy duty construction work,23kgs in weight, engine sound and light system included.

Originated from world famous engineering construction machine,massive power for heavy duty construction work,23kgs weight,streamline profile designing,powerful engine sound soul plus dazzling light system,it will be the most popular rc dumper in the world!

• Material: steel, zinc alloy and plastic

• Custom 9 channel 2.4Ghz radio

• Optimized steel hydraulic system

• Efficient under carriage

• Scale operator station (with driving figure)

• Diecast zinc alloy Axles

• Reliable hydraulic valve and adjustable pump

• Engine sound module equipped

• Light System Installed

• Max undercarriage steering 40 degrees

• Hydraulic steering system

• Brushless driving system

• 6×6 driving mode with differential

• 800Kv brushless monster torque motor

• Battery: Lipo 3S,4200mAh,11.1V

• Steel machined hydraulic pump

• Scale: 1:14

• Length: 900mm

• Width: 255mm

• Weight: 23kg

What’s Include:

A Ready-To-Run 1/14 RC Hydraulic Articulated Dumper with Radio Controll,with sound module&Light Module, with battery!

There are no reviews yet.